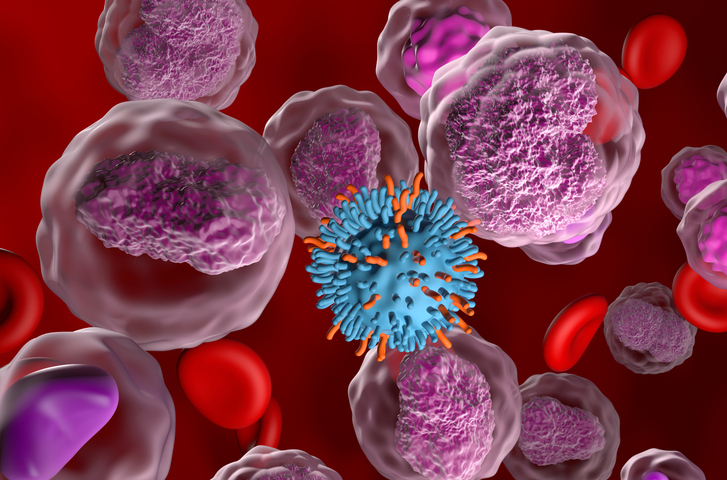

CAR-T (chimeric antigen receptor T-cell) therapies represent one of the most promising advances in personalized cancer treatment, but their production remains both costly and logistically complex. The primary hurdle lies in the nature of CAR-T therapy itself: each treatment is tailor-made for an individual patient using their own immune cells. This makes it difficult to scale production through traditional centralized manufacturing systems, which are typically designed for mass-producing uniform drug products.

Unlike conventional drugs that are produced in large batches and distributed globally, CAR-T therapies must be created on a patient-by-patient basis. The process begins with collecting a patient’s T cells through a procedure called leukapheresis. These cells are then sent to a manufacturing facility, where they are genetically modified to express a chimeric antigen receptor that targets cancer cells. After a brief period of cell expansion and quality control testing, the modified cells are returned and infused back into the same patient.

This individualized approach presents several production issues. First, it extends lead times for therapy delivery, which can be critical for patients with aggressive cancers. Second, it requires complex logistics and coordination across geographically distant locations. Third, it results in high production costs due to the labor-intensive and highly regulated nature of handling and modifying human cells.

Experts and industry leaders increasingly suggest that decentralized or point-of-care manufacturing could be a more sustainable model for CAR-T therapies. This approach proposes manufacturing the therapy at or near the site of clinical administration—such as local hospitals or dedicated cleanrooms—thereby reducing transport time, improving turnaround, and potentially lowering costs. Innovations in automated cell-processing platforms and modular cleanroom infrastructure may further support this transition.

Ultimately, the success and wider adoption of CAR-T therapies will depend heavily on resolving these production challenges. Moving away from centralized production models towards more decentralized, patient-centered manufacturing solutions may play a crucial role in achieving that goal and making these life-saving therapies more accessible.

Source: https:// – Courtesy of the original publisher.